Introduction:

The Metrology market industry is projected to grow from USD 10.00 Billion in 2022 to USD 15.44 billion by 2030, exhibiting a compound annual growth rate (CAGR) of 6.40% during the forecast period (2022 - 2030). In today's fast-paced and technologically advanced world, precision and accuracy have become crucial factors in various industries. From manufacturing and aerospace to healthcare and automotive sectors, the demand for precise measurements and quality assurance is paramount. This is where metrology comes into play, serving as the backbone for ensuring accuracy and efficiency in production processes. In this blog, we will explore the fascinating world of metrology and how it is revolutionizing industries across the globe.

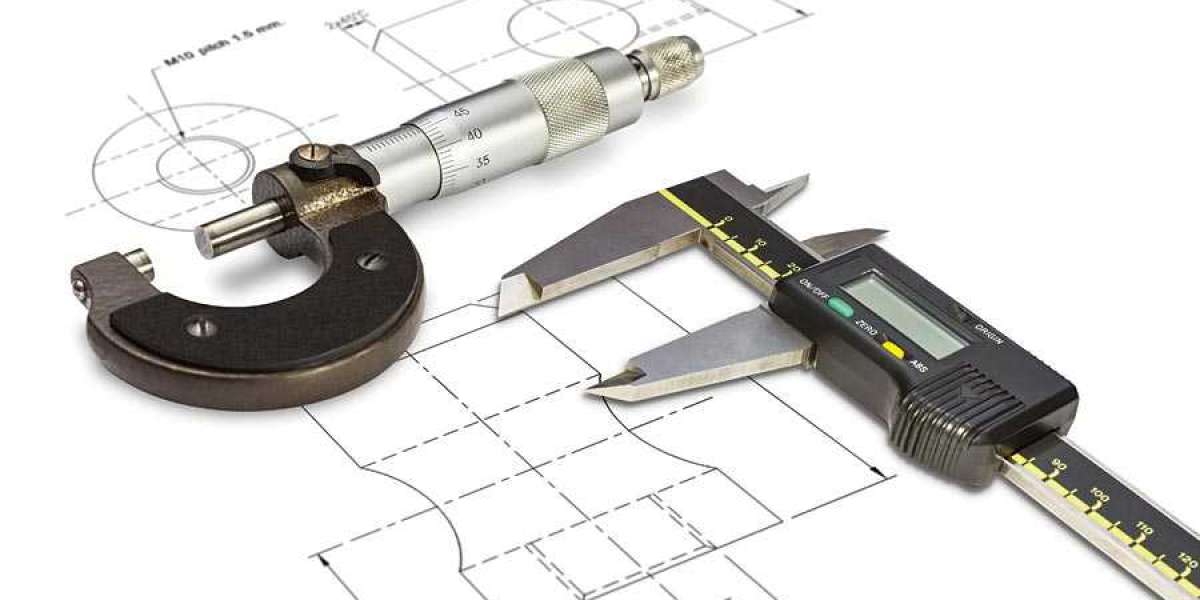

Understanding Metrology:

Metrology is the scientific study and application of measurement. It involves the development and use of measurement standards, techniques, and equipment to ensure accuracy and reliability in various fields. The primary objective of metrology is to establish traceability, which enables measurements to be linked to a recognized reference point, ensuring consistency and comparability.

Free Sample Copy - Obtain a free copy of our sample report to get a taste of our research expertise.

Key Players

- Hexagon (Sweden)

- ZEISS (Germany)

- Bird (US)

- Solayl SAS (France)

- Telemark (US)

- Hiden Analytical Ltd (UK)

- PLASMA SENSORS (US)

- TEGAM Inc. (US)

- MKS Instruments (US)

- INFICON (Switzerland)

- ARIS Technology (US)

- Accurate (India)

- Vision Engineering Ltd (UK)

- FARO (US)

- Keyence Corporation (Japan)

- Nikon Corporation (Japan)

- Mitutoyo America Corporation (Japan)

- Jenoptik (Sweden)

- Renishaw (UK)

- KLA Corporation (US)

Metrology in Industries:

- Manufacturing Industry: The manufacturing industry relies heavily on metrology for quality control and process optimization. With advanced measurement technologies such as coordinate measuring machines (CMMs) and 3D scanners, manufacturers can accurately inspect and validate the dimensions and geometries of their products. This ensures compliance with design specifications and minimizes defects, leading to improved product quality and reduced production costs.

- Aerospace Industry: The aerospace industry demands the highest level of precision due to the complexity and safety-critical nature of its components. Metrology plays a vital role in the aerospace sector by ensuring the accurate measurement of aircraft parts, such as turbine blades and landing gear. This helps maintain structural integrity, reduce material waste, and enhance overall aircraft performance.

- Healthcare Industry: Metrology is also revolutionizing the healthcare industry by enabling precise and reliable medical measurements. From diagnostic equipment calibration to the manufacturing of prosthetic devices, metrology ensures accurate and consistent results, enhancing patient safety and improving healthcare outcomes.

- Automotive Industry: In the automotive sector, metrology plays a crucial role in ensuring the dimensional accuracy of components and assemblies. With the advent of autonomous vehicles and electric mobility, the demand for precise measurements has increased significantly. Metrology tools, such as laser scanners and optical measuring systems, enable automotive manufacturers to optimize production processes, improve vehicle performance, and enhance driver safety.

Technological Advancements in Metrology:

The field of metrology continues to evolve with technological advancements, enabling more accurate and efficient measurements. Some notable advancements include:

- 3D Metrology: Three-dimensional metrology has revolutionized the measurement process by capturing the complete geometry of objects. Techniques such as laser scanning and structured light scanning enable rapid and precise measurements of complex shapes, facilitating faster inspection and reducing time-to-market.

- Non-Contact Metrology: Non-contact measurement techniques, such as optical and laser-based systems, eliminate the need for physical contact with the object being measured. This not only reduces the risk of damage but also allows for measurements of delicate or sensitive materials. Non-contact metrology is particularly valuable in industries like electronics and semiconductors.

- Portable Metrology: The advent of portable metrology devices has brought measurement capabilities directly to the production floor. Portable coordinate measuring machines and handheld laser scanners provide flexibility, allowing measurements to be taken in situ. This eliminates the need for transporting large components to metrology labs, saving time and cost.

Related Reports

Conclusion:

Metrology has become an indispensable tool across various industries, ensuring accuracy, quality, and efficiency. From manufacturing and aerospace to healthcare and automotive sectors, the impact of metrology is undeniable. As technology continues to advance, the field of metrology will continue to evolve, enabling even more precise measurements and driving innovation in industries worldwide. With the relentless pursuit of accuracy, metrology is revolutionizing the way we manufacture, build, and improve the world around us.