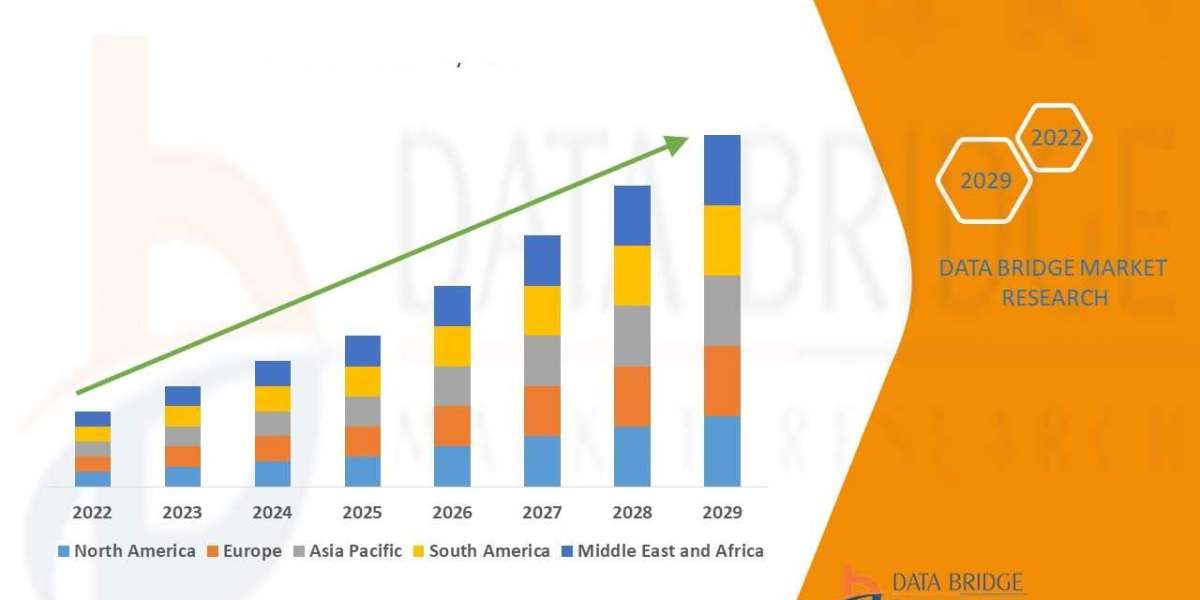

The Linux Operating System Market CAGR of 19.8% is projected to grow from USD 6.27 billion in 2022 to USD 22.15 billion by 2029.

The Oracle Linux operating system with cloud computing tools in a single support system and Red Hat Enterprise Linux operating system platforms are examples of well-known players we have taken into account when defining the scope of the project. Additionally, SUSE Group offers SUSE Linux Enterprise Server SUSE, which enables administrators and developers to deploy business workloads both on-premises and in the cloud. It is simple to use and manage. The IBM Corporation provides quick and secure Linux operating systems. Global data center, cloud, and server growth, as well as rising internet adoption, are the main factors driving the market's expansion.

Get a Free Sample PDF Report to learn more about The Linux Operating System Market.

https://www.fortunebusinessinsights.com/enquiry/sample/linux-operating-system-market-103037

DEMANDING INDUSTRY PLAYERS

The business provides a cost-effective Linux operating system that is user-friendly, dependable, and secure for both commercial and individual users. In order to integrate data, transactions, and insights, IBM Corporation offers enterprise platforms like IBM Z and LinuxONE OS. Red Hat, SUSE Group, and Canonical (Ubuntu) all count IBM Corporation as a significant distribution partner.

In order to maintain their competitiveness in the market, the top players are implementing a variety of business strategies, including new product launches, partnerships, mergers, and acquisitions.

The companies that follow are a few of the major businesses profiled:

- Amazon Web Services, Inc. (U.S.)

- Canonical Ltd. (U.K.)

- IBM Corporation (U.S.)

- Oracle Corporation (U.S.)

- ClearCenter (U.S.)

- Debian Project (U.S.)

- Elementary, Inc. (U.S.)

- Slackware Linux Project (U.S.)

- Zorin Group (Ireland)

- MontaVista Software, LLC (U.S.)

- Plesk International GmbH (Canada)

- SUSE Group (Germany)

The "Linux Operating System Market Report 2020" from Fortune Business Insights is an in-depth overview of the market that covers over 60 geographies and provides high-level market segmentation for each one. The market in each geography is examined, along with market size by region and country, in the section on regional and national breakdowns. Additionally, it assesses the market's past and anticipated growth and highlights important trends and corporate expansion tactics.

Click here to learn more about the most recent developments in the Linux Operating System Market. Linux Operating System Market Size, Share Forecast [2029]

SCOPE AND SEGMENTATION ASSOCIATED WITH REPORT

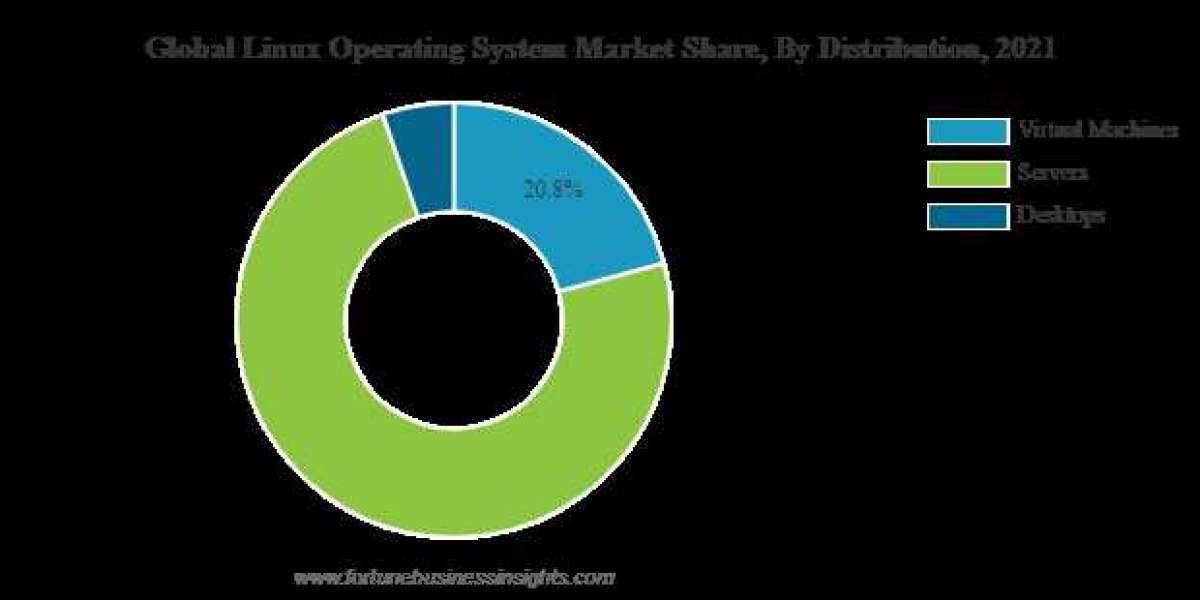

By Distribution:

- Virtual Machines

- Servers

- Desktops

By End-use:

- Commercial/Enterprise

- Individual

By Geography:

- North America (the U.S. and Canada)

- Europe (U.K., Germany, France, Italy, and the Rest of Europe)

- Asia-Pacific (Japan, China, India, Southeast Asia, and the Rest of Asia- Pacific)

- Latin America (Brazil, Mexico, and the Rest of Latin America)

- The Middle East and Africa (South Africa, GCC, and the Rest of the Middle East and Africa)

In order to understand the industry, the study looks at a number of crucial aspects, including the most recent market dynamics, growth potential, and development trends, as well as industry challenges, development threats, and risk factors. This thorough market overview makes the information easy to comprehend. The study provides both short- and long-term market forecasts as well as an analytical viewpoint on the relevant global market sector.

Got Queries? Find out related information at

https://www.fortunebusinessinsights.com/linux-operating-system-market-103037

What insights does the Linux Operating System Market report provide to readers?

- Linux Operating System Market Fragmentation on the Basis of Product Type, End User, and Region

- Comprehensive assessment of upstream starting materials, downstream demand, and the present market landscape.

- Collaborations, RD projects, acquisitions, and product launches of each Linux Operating System Market player

- The various rules that governments have placed on using the Linux Operating System Market are described in detail.

The inspirations for investing in this report

- The research provides a detailed overview of the market by defining, describing, and classifying it.

- The study includes the SWOT analysis and business plans of each vendor in the industry.

- The report provides in-depth analyses of current market trends, trend forecasts, and growth drivers.

- The study offers a thorough analysis of the business's landscape, a competitive landscape analysis, and significant market strategies.

About Us:

Fortune Business Insights offers expert corporate analysis and accurate data, helping organizations of all sizes make timely decisions. We tailor innovative solutions for our clients, assisting them to address challenges distinct to their businesses. Our goal is to empower our clients with holistic market intelligence, giving a granular overview of the market they are operating in.

Contact:

Email: [email protected]

Phone: US +1 424 253 0390 / UK +44 2071 939123 / APAC: +91 744 740 1245