The automation of numerous procedures in agriculture in both harvest production and animal rearing has surged. One automation, utilizing machines on small and big ranches globally, has led toward developments in labor productivity, animal welfare, and variations in the standard of life for farm owners and workers.

The milking routine is undoubtedly the most time-taking and boring work in dairies, and its automation provides a big relief for most agriculturalists. The automatic milking system is not a completely novel technology, as the first automatic milking system was utilized in the Netherlands in 1993. The instant benefit of this technology is that it lets cows be milked numerous times daily, in the automated system, without the need for much human interference.

Relieving labor from the milking and other repetitive work is not the only benefit associated with this system. The fully automatic milking package also offers crucial info to the caretakers about the well-being, nutrition, welfare, and behavior of the cattle This provides producers with valued information that can be utilized in the decision-making process.

As per a study, 45% of dairy employees suffer wounds on the back and 40% on the neckline and shoulder joint, because of the labor-exhaustive milking procedure. Besides, agriculturalists requirement to be dedicated to milking in the early mornings and evenings every day without any off day, irrespective of their well-being and family responsibilities.

Indisputably, AMS has become a recognized technology in the contemporary dairy sector and is progressively becoming mainstream practice due to its capability to advance working situations, milking frequency, milk yield, udder health, milk quality, and animal welfare.

Key Advantages of Automatic Milking Systems

Milk Quality

Milk quality includes hygienic standard and nutritious composition, with the vital parameters being total bacterial count, somatic cell count, anaerobic spores, freezing point, free fatty acids, and the content of protein, fat, casein, lactose, and urea. As per a study by Pomiès and Bony, automatic milking systems did not significantly change the milk’s hygienic quality. Some studies say that the milk quality in the AMS was comparable to non-automated milking and, in some cases, was greater.

Low-Stress Cow Environment

The evidence says that cows are profoundly impacted by stress in their surroundings. Yelling, loud noise, and screeching are very stressful to cows. Besides, cows are beings with robust social interaction. They repeatedly subordinate with the same cows, and tinier cows tend to evade the company of more aggressive ones.

In a robotic facility, a cow is free to follow her natural biorhythm, rather than limiting the schedule of the dairy operator. The cow is now completely in charge of when she will eat, lay down and go to be milked. No longer is the interference of a human in the cow environment related to having to get up to stand in a farm area to wait to be milked.

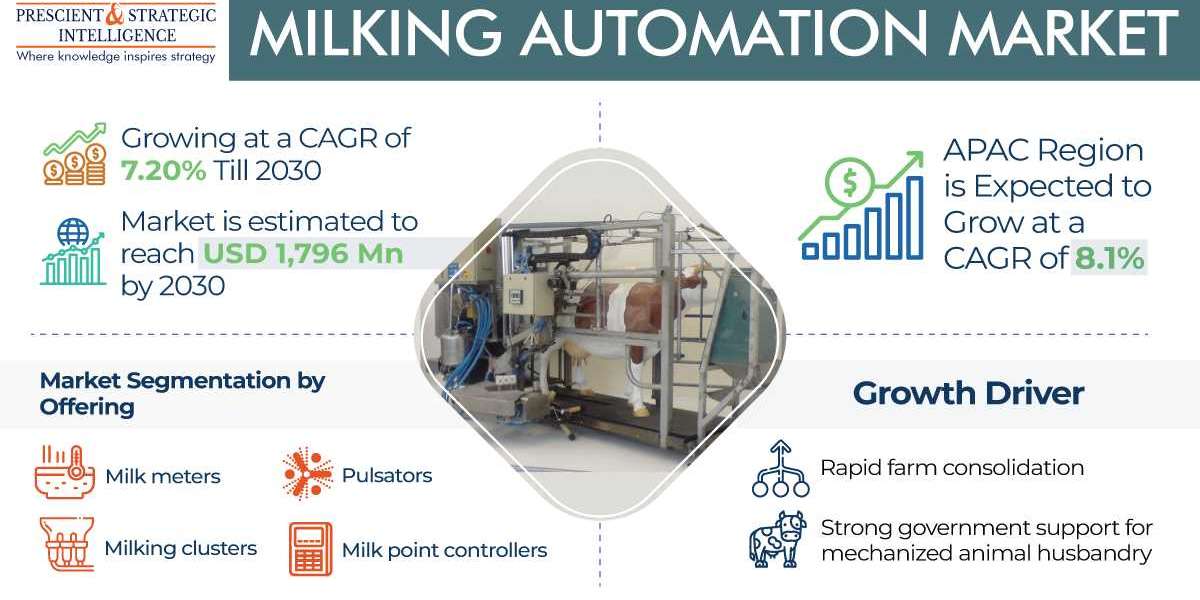

Hence, the milking automation market is experiencing growth and is projected to reach USD 1,796 million by 2030.